AHS is quietly expanding

Published 12:00 am Wednesday, March 31, 2021

- Tracy Frazier, professional development and project design, president Jermaine Fulks and Ironton Mayor Sam Cramblit stand in the office of American Hydraulics Services on First Street in Ironton. The company began in Catlettsburg, Kentucky 25 years ago and expanded into Ironton to do industrial manufacturing. (The Ironton Tribune | Mark Shaffer)

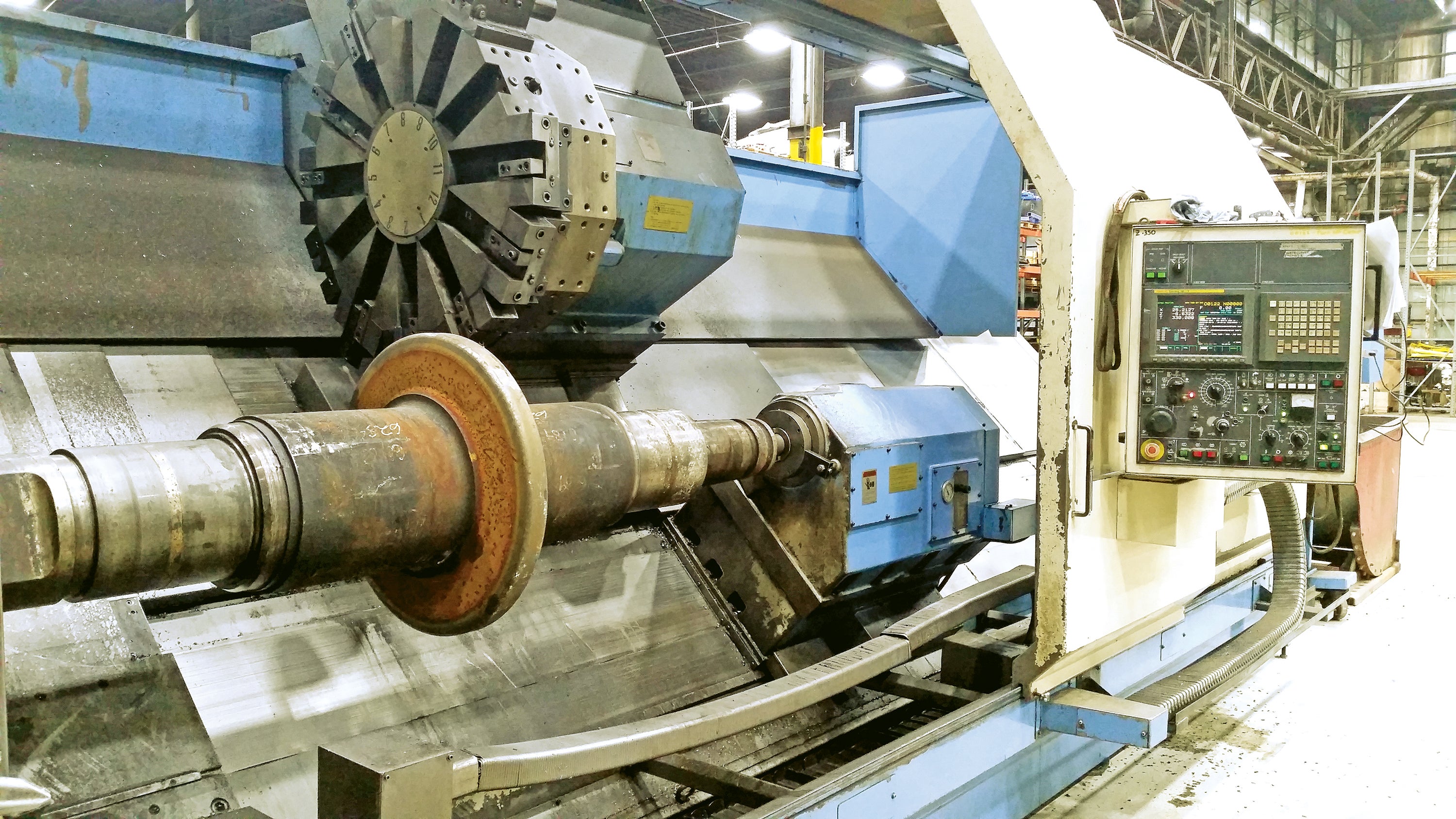

A large industrial lathe that can turn metal rods into machine parts at American Hydraulics Services on First Street in Ironton. (The Ironton Tribune | Mark Shaffer)

Hydraulic repair company came to Ironton to start manufacturing

American Hydraulics Services in Ironton began in 2018, an expansion of their machine shop business in Catlettsburg, Kentucky.

The Catlettsburg shop, known as AHS-KY, was started in 1995 and the expanded into Ironton because of the need for more space. They found that space along the end of First Street where they have a building with 65,000 square feet and opened up AHS-OH.

Jerimiah Fulks founded AHS in Catlettsburg in 1995 and the shop specialized in repairing and rebuilding hydraulic systems. Over the years, the company moved into other areas like construction, welding, metal fabrication, plant maintenance, machine lathing, equipment repair and fabricating parts from small machine parts to massive projects like a multi-ton steel pallet. They work with a large industrial tri-state company.

But they don’t work with just big companies, said Tracy Frazier, who is over professional development and project design.

“Aside from industrial manufacturing, we also work with small customers. So, if there is a guy working on his tractor and has a cylinder go bad, he can bring it into our shop in Catlettsburg to get it repaired,” he said. The same goes for small companies that might be having an issue with a pump. “We do small repairs and maintenance along with what we are now focusing on, which is industrial manufacturing, which will become the primary segment for our business this year.”

Much of the things they are manufacturing now falls under the realm of proprietary information and they don’t talk about it because they don’t want their client’s competitors to know about it.

Fulks said the Ironton shop is for the industrial division for the company.

“Some of the projects we do are massive,” he said.

One pallet they are building is massive, welded-steel piece, a dozen feet square. A large water tank will sit on top of it and the whole thing can be moved to different locations at a manufacturing plant.

“It will be 150 ton when it is all done,” Fulks said. They have orders for steel pallets for other industrial use. “The stars are aligning for us here in Ironton. It’s exciting.”

One interesting piece of equipment they have is a machine that does dynamic testing of hydraulic cylinders, up to 31 feet tall, and their full range of motion up to 600 tons of pressure. The testing is requested by a lot of mining companies.

“It’s the only one anywhere in the U.S., outside of the federal government,” Fulks said. “My business partner, Randal Blankenship, came up with it. He’s a very talented man.”

Blankenship is the vice president of AHS and is an engineer who specializes in hydraulics.

Fulks said what he likes about Ironton is the community.

“It is very business friendly in Ohio and the community here, we can see what we are doing in this community,” he said. “And the City of Ironton has been great to us.”

Frazier said they have a great relationship with Mayor Sam Cramblit.

“He’s pro-business, he’s making things happen,” he said.

Cramblit said the main part has been speaking with Fulks and learning what the company’s needs are.

“So far, we have been able to acquire grant money from the Appalachian Regional Commission to build them a road so they can transport their items out of their facility, so trucks can travel this road and make their facility more accessible,” he said. “And we are going to be here to help with their future developments all we can. I love having them here, that’s why I’m doing everything I can to help them.”

Frazier said that the company has plans to expand, planning on adding an additional 10,000 square foot building at their Ironton location as the demand for manufacturing expands.

And the company is looking to hire qualified workers to do CNC programmers, certified welders and first class manual machinists.

“It’s really hard to find those workers, we are going to be relying on the training opportunities locally to develop some specified training programs,” Frazier said. “We aren’t quite ready to make on workers and train them in it yet, but that will happen. We will eventually bring in some motivated young people to serve apprenticeships and go through local training programs.”